What are the Manufacturing Processes of the Latest Fan Capacitors?

I. Introduction

Fan capacitors are essential components in electrical systems, particularly in electric motors used in fans, air conditioners, and various appliances. These capacitors play a crucial role in enhancing motor efficiency, improving energy consumption, and ensuring the smooth operation of devices. As technology advances, the manufacturing processes of fan capacitors have evolved, incorporating new materials and techniques to meet the demands of modern applications. This article aims to provide an in-depth look at the manufacturing processes of the latest fan capacitors, exploring the raw materials used, the steps involved in production, and the innovations shaping the industry.

II. Understanding Fan Capacitors

A. Types of Fan Capacitors

Fan capacitors can be broadly categorized into two types: run capacitors and start capacitors.

1. **Run Capacitors**: These capacitors are used in continuous operation applications, providing a steady voltage to the motor. They help improve the efficiency of the motor by maintaining a consistent phase difference between the current and voltage.

2. **Start Capacitors**: These capacitors are designed for short-term use, providing an initial boost of energy to start the motor. Once the motor reaches a certain speed, the start capacitor is typically disconnected from the circuit.

B. Functionality and Applications

Fan capacitors are integral to the functionality of electric motors. They enhance motor efficiency by improving the power factor, which reduces energy consumption. This is particularly important in applications where motors run continuously, such as in HVAC systems and industrial fans. Recent advancements in fan capacitor technology have led to the development of more compact and efficient designs, further optimizing energy use.

III. Raw Materials Used in Fan Capacitor Manufacturing

The manufacturing of fan capacitors involves a variety of raw materials, each selected for its specific properties.

A. Dielectric Materials

Dielectric materials are crucial for the capacitor's function, as they store electrical energy. Common dielectric materials include:

1. **Polypropylene**: Known for its high dielectric strength and low loss factor, polypropylene is widely used in fan capacitors.

2. **Polyester**: This material offers good thermal stability and is often used in applications requiring moderate capacitance.

3. **Ceramic**: Ceramic capacitors are known for their reliability and stability, making them suitable for high-frequency applications.

B. Conductive Materials

Conductive materials are essential for the capacitor's ability to conduct electricity. The most commonly used conductive materials are:

1. **Aluminum**: Lightweight and cost-effective, aluminum is often used for the capacitor's plates.

2. **Copper**: Known for its excellent conductivity, copper is sometimes used in high-performance capacitors.

C. Insulating Materials

Insulating materials are used to prevent electrical leakage and ensure safety. Common insulating materials include:

1. **Epoxy Resins**: These materials provide excellent insulation and are often used in the encapsulation process.

2. **PVC**: Polyvinyl chloride is used for its durability and resistance to environmental factors.

D. Environmental Considerations in Material Selection

Manufacturers are increasingly considering environmental factors when selecting materials. This includes choosing recyclable materials and minimizing the use of harmful substances to comply with regulations such as RoHS (Restriction of Hazardous Substances).

IV. Manufacturing Processes of Fan Capacitors

The manufacturing of fan capacitors involves several key processes, each critical to ensuring the final product meets quality and performance standards.

A. Design and Engineering

The manufacturing process begins with design and engineering.

1. **Computer-Aided Design (CAD) Tools**: Engineers use CAD software to create detailed designs of the capacitors, optimizing dimensions and materials for performance.

2. **Prototyping and Testing**: Prototypes are created to test the design's functionality and performance. This stage is crucial for identifying any potential issues before mass production.

B. Dielectric Film Production

The dielectric film is a core component of the capacitor.

1. **Film Extrusion Process**: The dielectric material is extruded into thin films, which are then cut to the required dimensions.

2. **Thickness and Quality Control**: The thickness of the film is critical for performance, and quality control measures are implemented to ensure consistency.

C. Capacitor Assembly

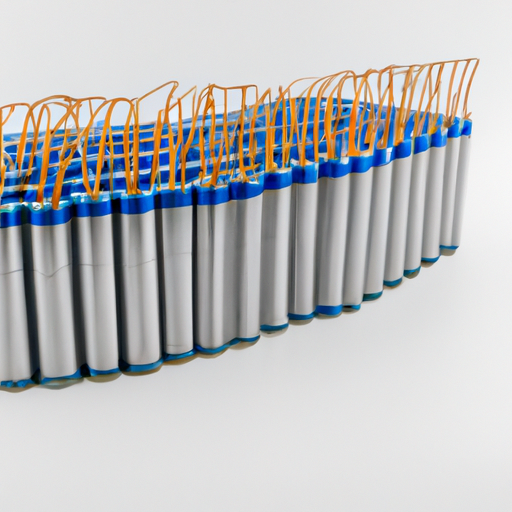

The assembly process involves layering and combining the dielectric and conductive materials.

1. **Layering of Dielectric and Conductive Materials**: The dielectric film is layered with conductive materials, creating the capacitor's structure.

2. **Winding and Stacking Techniques**: Depending on the design, the layers may be wound into a cylindrical shape or stacked flat to form the capacitor.

D. Encapsulation and Insulation

Once assembled, the capacitor must be insulated and encapsulated.

1. **Application of Insulating Materials**: Insulating materials are applied to prevent electrical leakage and protect the capacitor from environmental factors.

2. **Methods of Encapsulation**: Various methods, such as potting and molding, are used to encapsulate the capacitor, ensuring durability and reliability.

E. Quality Control and Testing

Quality control is a critical step in the manufacturing process.

1. **Electrical Testing**: Each capacitor undergoes electrical testing to verify capacitance, voltage rating, and other performance metrics.

2. **Mechanical Testing**: Mechanical tests, such as vibration and thermal cycling, ensure the capacitor can withstand operational stresses.

3. **Compliance with Industry Standards**: Manufacturers must ensure their products comply with industry standards, such as UL (Underwriters Laboratories) and IEC (International Electrotechnical Commission) regulations.

V. Innovations in Fan Capacitor Manufacturing

The fan capacitor manufacturing industry is witnessing several innovations that enhance production efficiency and product performance.

A. Automation and Robotics in Production

Automation and robotics are increasingly being integrated into the manufacturing process, improving precision and reducing labor costs. Automated systems can handle repetitive tasks, allowing human workers to focus on more complex operations.

B. Smart Capacitors and IoT Integration

The rise of the Internet of Things (IoT) has led to the development of smart capacitors that can communicate with other devices. These capacitors can monitor performance in real-time, providing data that can be used to optimize energy consumption and maintenance schedules.

C. Sustainable Manufacturing Practices

Sustainability is becoming a priority in manufacturing.

1. **Recycling of Materials**: Manufacturers are exploring ways to recycle materials used in capacitor production, reducing waste and environmental impact.

2. **Energy-Efficient Production Methods**: Implementing energy-efficient practices in manufacturing processes helps reduce the overall carbon footprint.

D. Future Trends in Fan Capacitor Technology

As technology continues to evolve, future trends may include the development of even more efficient materials, enhanced smart capabilities, and further integration of sustainable practices in manufacturing.

VI. Challenges in Fan Capacitor Manufacturing

Despite advancements, the manufacturing of fan capacitors faces several challenges.

A. Supply Chain Issues for Raw Materials

Global supply chain disruptions can impact the availability and cost of raw materials, affecting production timelines and pricing.

B. Meeting Regulatory Requirements

Manufacturers must navigate complex regulatory environments, ensuring compliance with various standards while maintaining product quality.

C. Balancing Cost and Quality

Finding the right balance between cost and quality is a constant challenge. Manufacturers must invest in high-quality materials and processes while keeping production costs competitive.

D. Adapting to Rapid Technological Changes

The fast pace of technological change requires manufacturers to stay ahead of trends and continuously innovate to meet market demands.

VII. Conclusion

Fan capacitors are vital components in modern electrical systems, playing a crucial role in motor efficiency and energy consumption. The manufacturing processes of these capacitors have evolved significantly, incorporating advanced materials and techniques to enhance performance and sustainability. As the industry continues to innovate, the future of fan capacitor technology looks promising, with opportunities for further research and development. Manufacturers must remain agile, adapting to challenges and embracing new technologies to meet the demands of a rapidly changing market.

VIII. References

1. Academic journals and articles on capacitor technology and manufacturing processes.

2. Industry reports and white papers detailing advancements in fan capacitor technology.

3. Manufacturer specifications and guidelines for fan capacitors.

4. Relevant standards and regulations governing capacitor manufacturing and safety.

This comprehensive overview of fan capacitor manufacturing processes highlights the importance of these components in electrical systems and the ongoing innovations shaping their production. As the industry evolves, continued research and development will be essential to meet the growing demands for efficiency and sustainability.