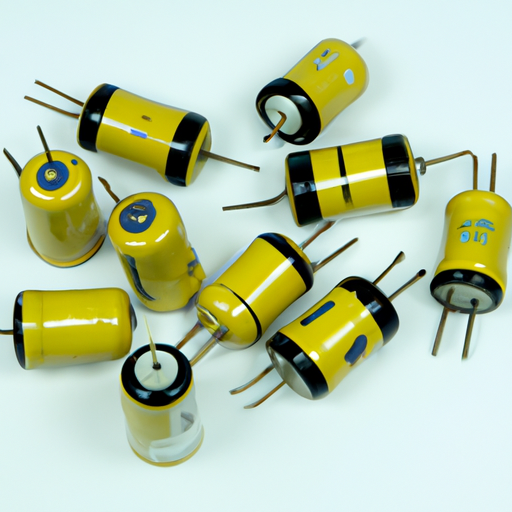

Popular Models of Common Overload Capacitors

I. Introduction

In the realm of electrical systems, overload capacitors play a crucial role in ensuring the smooth operation of various devices and machinery. These components are designed to handle excess electrical loads, providing stability and efficiency in circuits. This article aims to explore the significance of overload capacitors, their functionality, common applications, popular models, and essential factors to consider when selecting the right capacitor for your needs.

II. Understanding Overload Capacitors

A. What are Overload Capacitors?

Overload capacitors are electrical components that store and release electrical energy in a circuit. They are primarily used to manage excess voltage and current, preventing damage to electrical devices.

1. Function and Role in Electrical Circuits

The primary function of overload capacitors is to provide a temporary energy reserve that can be tapped into during peak demand periods. This helps to stabilize voltage levels and improve the overall efficiency of electrical systems.

2. Types of Overload Capacitors

There are several types of overload capacitors, including:

Start Capacitors: Used in single-phase motors to provide an initial boost of energy for starting.

Run Capacitors: Employed in motors to improve efficiency during operation.

Power Factor Correction Capacitors: Used to improve the power factor in electrical systems, reducing energy losses.

B. How Overload Capacitors Work

1. Basic Principles of Operation

Overload capacitors operate on the principle of storing electrical energy in an electric field. When voltage is applied, the capacitor charges, and when the circuit requires additional energy, the capacitor discharges, providing the necessary power.

2. Key Specifications and Ratings

When selecting an overload capacitor, it is essential to consider its specifications, including:

Voltage Rating: The maximum voltage the capacitor can handle.

Capacitance Value: The amount of electrical charge the capacitor can store, measured in microfarads (µF).

Temperature Rating: The range of temperatures in which the capacitor can operate effectively.

III. Common Applications of Overload Capacitors

A. Industrial Applications

1. Motor Start Capacitors

In industrial settings, motor start capacitors are vital for providing the necessary torque to start large motors. These capacitors are designed to handle high inrush currents and are typically used in applications such as pumps, compressors, and conveyor systems.

2. Power Factor Correction

Power factor correction capacitors are used in industrial environments to improve the efficiency of electrical systems. By reducing reactive power, these capacitors help lower energy costs and improve the overall performance of electrical equipment.

B. Residential Applications

1. HVAC Systems

In residential settings, overload capacitors are commonly found in HVAC systems. They help start and run the compressor and fan motors, ensuring efficient operation and comfort in homes.

2. Home Appliances

Many household appliances, such as refrigerators and washing machines, utilize overload capacitors to enhance performance and energy efficiency. These capacitors help manage the electrical load during operation, preventing potential damage to the appliance.

C. Commercial Applications

1. Lighting Systems

In commercial lighting systems, overload capacitors are used to improve energy efficiency and reduce flickering. They help stabilize voltage levels, ensuring consistent lighting performance.

2. Elevators and Escalators

Overload capacitors are also essential in elevators and escalators, providing the necessary power to start and operate these systems smoothly. They help manage the electrical load during peak usage times, ensuring safety and reliability.

IV. Popular Models of Overload Capacitors

A. Overview of Leading Manufacturers

Several manufacturers are known for producing high-quality overload capacitors. Here, we will explore three leading brands and their popular models.

1. Manufacturer A: [Brand Name]

Product Line and Features: Manufacturer A offers a range of overload capacitors designed for various applications, including motor start and run capacitors. Their products are known for high reliability and efficiency.

Typical Applications: Commonly used in HVAC systems and industrial motors.

2. Manufacturer B: [Brand Name]

Product Line and Features: Manufacturer B specializes in power factor correction capacitors, providing solutions for both residential and commercial applications. Their capacitors are designed to enhance energy efficiency and reduce costs.

Typical Applications: Widely used in industrial settings and commercial buildings.

3. Manufacturer C: [Brand Name]

Product Line and Features: Manufacturer C offers a diverse range of overload capacitors, including high-voltage options for specialized applications. Their products are known for durability and long lifespan.

Typical Applications: Used in heavy machinery and large electrical systems.

B. Comparison of Popular Models

When comparing popular models of overload capacitors, several factors come into play:

1. Capacitor Ratings (Voltage, Capacitance, etc.)

Different models come with varying voltage and capacitance ratings. It is essential to choose a capacitor that meets the specific requirements of your application.

2. Durability and Lifespan

The durability and lifespan of a capacitor are critical factors to consider. High-quality capacitors are designed to withstand harsh conditions and have a longer operational life.

3. Cost and Availability

Cost is always a consideration when selecting electrical components. It is essential to find a balance between quality and affordability, ensuring that you choose a capacitor that fits your budget while meeting your performance needs.

V. Factors to Consider When Choosing Overload Capacitors

A. Application Requirements

1. Load Type and Characteristics

Understanding the type of load your capacitor will be handling is crucial. Different applications may require specific capacitor types, such as start or run capacitors.

2. Environmental Conditions

Consider the environmental conditions in which the capacitor will operate. Factors such as temperature, humidity, and exposure to chemicals can impact the performance and lifespan of the capacitor.

B. Electrical Specifications

1. Voltage Rating

Ensure that the voltage rating of the capacitor matches or exceeds the voltage of your electrical system to prevent failure.

2. Capacitance Value

Select a capacitor with the appropriate capacitance value for your application. This will ensure optimal performance and efficiency.

C. Regulatory Standards and Compliance

It is essential to choose capacitors that comply with industry standards and regulations. This ensures safety and reliability in your electrical systems.

VI. Maintenance and Troubleshooting of Overload Capacitors

A. Signs of Overload Capacitor Failure

Recognizing the signs of capacitor failure is crucial for maintaining electrical systems. Common indicators include:

- Unusual noises or humming sounds

- Overheating

- Reduced performance of connected devices

B. Best Practices for Maintenance

Regular maintenance of overload capacitors can extend their lifespan and improve performance. Best practices include:

- Periodic inspections for signs of wear or damage

- Cleaning terminals and connections

- Ensuring proper ventilation to prevent overheating

C. Troubleshooting Common Issues

If you encounter issues with overload capacitors, troubleshooting steps may include:

- Checking for loose connections

- Testing voltage and capacitance with a multimeter

- Replacing faulty capacitors as needed

VII. Conclusion

Overload capacitors are essential components in various electrical systems, providing stability and efficiency. Understanding their functionality, applications, and popular models can help you make informed decisions when selecting the right capacitor for your needs. By considering factors such as application requirements, electrical specifications, and maintenance practices, you can ensure optimal performance and longevity of your electrical systems.

As technology continues to evolve, further research and learning about overload capacitors will empower you to stay ahead in the ever-changing landscape of electrical engineering.

VIII. References

A. Suggested Reading and Resources

- Electrical Engineering Textbooks

- Online Courses on Electrical Components

B. Industry Standards and Guidelines

- National Electrical Manufacturers Association (NEMA)

- Institute of Electrical and Electronics Engineers (IEEE)

C. Manufacturer Websites and Product Catalogs

- [Manufacturer A Website]

- [Manufacturer B Website]

- [Manufacturer C Website]

This comprehensive overview of popular models of common overload capacitors provides valuable insights for anyone looking to understand and utilize these critical components in electrical systems.