What are the Top 10 Popular Models of Standard Resistors?

Introduction

Resistors are fundamental components in electronic circuits, playing a crucial role in controlling current flow, dividing voltages, and protecting sensitive components. They are essential for ensuring that electronic devices function correctly and reliably. Among the various types of resistors, standard resistors are particularly important for calibration and measurement purposes, providing a reference point for other components. This article aims to explore the top 10 popular models of standard resistors, highlighting their specifications, applications, and significance in the electronics industry.

Section 1: Understanding Resistors

1.1 Definition of Resistors

A resistor is a passive electrical component that opposes the flow of electric current, resulting in a voltage drop across its terminals. The primary function of a resistor is to limit current, divide voltages, and dissipate energy in the form of heat. Resistors are characterized by their resistance value, measured in ohms (Ω), and are used in various applications, from simple circuits to complex electronic devices.

1.2 Types of Resistors

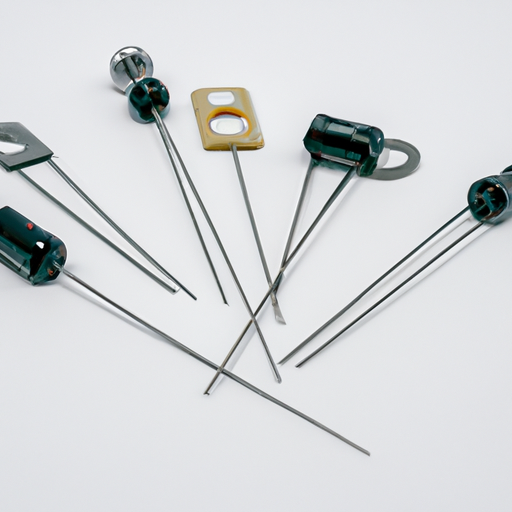

Resistors can be categorized into several types based on their construction and functionality. The two main categories are:

Fixed Resistors: These resistors have a constant resistance value and are widely used in circuits. Examples include carbon film, metal film, and wirewound resistors.

Variable Resistors: These resistors allow the resistance value to be adjusted, making them suitable for applications like volume controls and tuning circuits. Examples include potentiometers and rheostats.

1.3 Importance of Standard Resistors

Standard resistors are precision components used for calibration and measurement in laboratories and industrial applications. They provide a reliable reference for testing and ensuring the accuracy of other electronic components. Their stability and precision make them indispensable in various fields, including telecommunications, automotive, and consumer electronics.

Section 2: Criteria for Popularity

2.1 Performance Characteristics

The popularity of specific resistor models is influenced by several performance characteristics, including:

Tolerance: The allowable deviation from the specified resistance value, typically expressed as a percentage. Lower tolerance values indicate higher precision.

Temperature Coefficient: This measures how much the resistance changes with temperature, expressed in parts per million per degree Celsius (ppm/°C). A lower temperature coefficient indicates better stability.

Power Rating: The maximum power a resistor can dissipate without overheating, usually measured in watts (W). Higher power ratings are essential for applications with significant current flow.

2.2 Availability and Cost

The availability of resistor models and their cost also play a significant role in their popularity. Models that are widely produced and readily available tend to be more popular among manufacturers and hobbyists. Additionally, cost-effective options without compromising quality are often preferred.

2.3 Applications

Different resistor models find applications in various electronic devices, from consumer electronics to industrial machinery. The versatility of certain models makes them more popular in specific sectors, such as automotive, telecommunications, and medical devices.

Section 3: Top 10 Popular Models of Standard Resistors

3.1 Model 1: 1/4W Carbon Film Resistor

The 1/4W carbon film resistor is one of the most commonly used resistors in electronic circuits. It offers good stability and low noise, making it suitable for general-purpose applications. With a tolerance of ±5% and a temperature coefficient of around 100 ppm/°C, it is ideal for use in consumer electronics, audio equipment, and signal processing.

3.2 Model 2: 1/4W Metal Film Resistor

Similar to the carbon film resistor, the 1/4W metal film resistor provides better precision and stability. With a tolerance of ±1% or ±2% and a lower temperature coefficient (typically around 50 ppm/°C), it is widely used in applications requiring high accuracy, such as instrumentation and precision circuits.

3.3 Model 3: 1/2W Carbon Composition Resistor

The 1/2W carbon composition resistor is known for its high energy absorption capability and is often used in high-voltage applications. While it has a higher tolerance (±5% to ±10%) and a higher temperature coefficient, it is still favored in applications where high pulse power is required, such as in power amplifiers and audio equipment.

3.4 Model 4: 1/2W Wirewound Resistor

Wirewound resistors are constructed by winding a metal wire around a ceramic or fiberglass core. The 1/2W wirewound resistor is known for its high power rating and excellent stability. With tolerances as low as ±1% and a temperature coefficient of around 20 ppm/°C, it is commonly used in power supplies, amplifiers, and industrial applications.

3.5 Model 5: 1/8W Thin Film Resistor

Thin film resistors are known for their high precision and low noise characteristics. The 1/8W thin film resistor offers tolerances as low as ±0.1% and a temperature coefficient of around 10 ppm/°C. These resistors are ideal for applications in precision measurement and high-frequency circuits.

3.6 Model 6: 1W Metal Oxide Resistor

The 1W metal oxide resistor is designed for high-temperature applications and offers excellent stability. With a tolerance of ±5% and a temperature coefficient of around 100 ppm/°C, it is commonly used in power circuits, automotive applications, and industrial equipment.

3.7 Model 7: 2W Power Resistor

The 2W power resistor is designed to handle higher power levels, making it suitable for applications in power electronics and motor control. With a tolerance of ±5% and a temperature coefficient of around 100 ppm/°C, it is often used in power supplies, amplifiers, and other high-current applications.

3.8 Model 8: SMD Resistors (0805, 0603)

Surface mount device (SMD) resistors, such as the 0805 and 0603 models, are popular in modern electronics due to their compact size and ease of integration into printed circuit boards (PCBs). They are available in various tolerances and power ratings, making them suitable for a wide range of applications, from consumer electronics to automotive systems.

3.9 Model 9: Precision Resistors

Precision resistors are designed for applications requiring high accuracy and stability. They typically have tolerances of ±0.1% or better and low temperature coefficients. These resistors are commonly used in measurement and calibration equipment, as well as in high-end audio and instrumentation applications.

3.10 Model 10: High Voltage Resistors

High voltage resistors are specifically designed to handle high voltage applications, often exceeding 1kV. They are constructed with materials that can withstand high electrical stress and are used in power supplies, RF applications, and other high-voltage circuits.

Section 4: Comparison of the Top Models

4.1 Performance Metrics

When comparing the top resistor models, performance metrics such as tolerance, temperature stability, and power handling are crucial. For instance, thin film and precision resistors excel in accuracy, while wirewound and power resistors are preferred for high power applications.

4.2 Cost Analysis

Cost is a significant factor in the selection of resistor models. While precision resistors may offer superior performance, they often come at a higher price. Conversely, carbon film and metal film resistors provide a balance of performance and cost, making them popular choices for general applications.

4.3 Application Suitability

Each resistor model has its strengths and weaknesses, making them suitable for specific applications. For example, carbon film resistors are ideal for general use, while precision resistors are essential for measurement and calibration tasks. Understanding the application requirements is key to selecting the right resistor model.

Section 5: Future Trends in Resistor Technology

5.1 Innovations in Resistor Design

As technology advances, innovations in resistor design are emerging. New materials and manufacturing techniques are being developed to enhance performance, reduce size, and improve thermal management. These innovations are expected to lead to more efficient and reliable resistor models in the future.

5.2 Market Trends

The demand for specific types of resistors is influenced by trends in various industries. For instance, the growing popularity of electric vehicles and renewable energy systems is driving the need for high power and precision resistors. Additionally, the increasing complexity of electronic devices is leading to a higher demand for compact SMD resistors.

Conclusion

Standard resistors are vital components in electronic circuits, providing essential functions in controlling current and ensuring accurate measurements. The top 10 popular models discussed in this article highlight the diversity and importance of resistors in modern electronics. As technology continues to evolve, understanding the characteristics and applications of these resistors will be crucial for engineers and hobbyists alike. Exploring resistor technology further can lead to better design choices and improved performance in electronic devices.

References

- Electronic Components: A Complete Reference for Engineers and Technicians

- Resistor Technology: A Comprehensive Guide

- Understanding Resistors: Types, Applications, and Specifications

- The Role of Resistors in Electronic Circuits: An Overview

- Innovations in Resistor Design: Trends and Future Directions