Popular Load Resistor Product Models

I. Introduction

A. Definition of Load Resistors

Load resistors are passive electrical components that provide a specific resistance to an electrical circuit. They are designed to dissipate electrical energy in the form of heat, simulating a load for testing and measurement purposes. By doing so, they help ensure that circuits operate correctly under various conditions.

B. Importance of Load Resistors in Electrical Engineering

In electrical engineering, load resistors play a crucial role in various applications, including testing circuits, power electronics, and motor control. They allow engineers to simulate real-world conditions, ensuring that devices function as intended before deployment. Their ability to handle power and provide accurate measurements makes them indispensable in both laboratory and industrial settings.

C. Purpose of the Article

This article aims to explore popular load resistor product models, highlighting their features, applications, and the leading manufacturers in the market. By the end, readers will have a comprehensive understanding of load resistors and how to select the right model for their specific needs.

II. Understanding Load Resistors

1. Functionality

Load resistors are used to create a controlled load in a circuit, allowing engineers to test the performance of power supplies, amplifiers, and other electronic devices. They can simulate various load conditions, helping to identify potential issues before they arise in real-world applications.

2. Types of Load Resistors

Load resistors come in various types, including wire-wound, thick film, and thin film resistors. Each type has its unique characteristics, making them suitable for different applications. Wire-wound resistors, for example, are known for their high power ratings, while thin film resistors offer superior accuracy and stability.

1. Testing and Measurement

Load resistors are commonly used in testing scenarios to simulate the load that a device will encounter in operation. This helps engineers evaluate performance metrics such as voltage, current, and power output.

2. Power Electronics

In power electronics, load resistors are essential for testing power supplies, converters, and inverters. They help ensure that these devices can handle the required load without overheating or failing.

3. Motor Control

Load resistors are used in motor control applications to simulate the load on a motor, allowing engineers to test control systems and ensure proper operation.

4. Audio Equipment

In audio applications, load resistors are used to test amplifiers and other audio devices, ensuring they can handle the expected load without distortion or failure.

III. Key Features of Load Resistors

A. Power Rating

The power rating of a load resistor indicates the maximum amount of power it can dissipate without overheating. This is a critical factor to consider when selecting a load resistor for a specific application.

B. Resistance Value

The resistance value determines how much current will flow through the resistor when a voltage is applied. It is essential to choose a resistor with the appropriate resistance value for the intended application.

C. Tolerance

Tolerance refers to the allowable variation in resistance value. A lower tolerance indicates a more precise resistor, which is crucial for applications requiring high accuracy.

D. Temperature Coefficient

The temperature coefficient indicates how much the resistance value changes with temperature. A low temperature coefficient is desirable for applications where temperature fluctuations are expected.

E. Construction Material

Load resistors can be made from various materials, including metal film, carbon film, and wire-wound elements. The choice of material affects the resistor's performance, including its power handling and thermal stability.

F. Size and Form Factor

The physical size and form factor of a load resistor can impact its application. Smaller resistors may be suitable for compact devices, while larger resistors may be necessary for high-power applications.

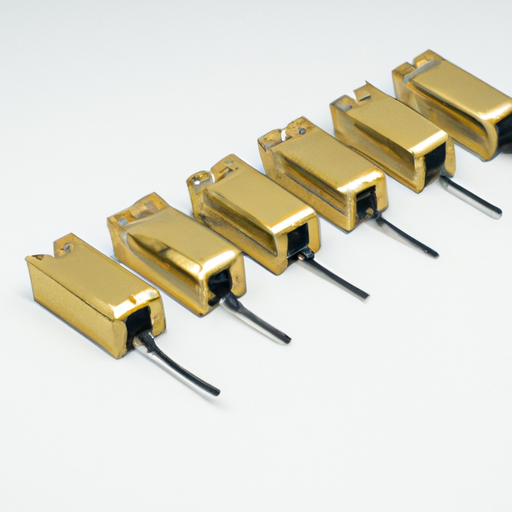

IV. Popular Load Resistor Product Models

A. Overview of Leading Manufacturers

Several manufacturers are known for producing high-quality load resistors. Some of the leading brands include:

1. Vishay

Vishay is a well-respected manufacturer known for its wide range of electronic components, including load resistors.

2. Ohmite

Ohmite specializes in resistive products and is recognized for its durable and reliable load resistors.

3. TE Connectivity

TE Connectivity offers a variety of load resistors designed for various applications, including automotive and industrial uses.

4. Bourns

Bourns is known for its innovative solutions in the resistor market, providing high-performance load resistors.

5. Caddock Electronics

Caddock Electronics focuses on precision resistors, making them a popular choice for applications requiring high accuracy.

1. Vishay's RGP Series

Specifications: The RGP series features power ratings ranging from 1W to 100W, with resistance values from 0.1Ω to 1MΩ.

Applications: Ideal for power electronics and testing applications, the RGP series is known for its thermal stability and reliability.

2. Ohmite's 2W Series

Specifications: This series offers a power rating of 2W with resistance values from 1Ω to 1MΩ.

Applications: The 2W series is commonly used in general-purpose applications, including audio equipment and motor control.

3. TE Connectivity's R-1 Series

Specifications: The R-1 series provides power ratings up to 5W and resistance values from 0.1Ω to 10MΩ.

Applications: Suitable for automotive and industrial applications, this series is designed for high reliability.

4. Bourns' 3300 Series

Specifications: The 3300 series features power ratings from 0.5W to 5W, with resistance values ranging from 1Ω to 1MΩ.

Applications: This series is ideal for testing and measurement applications, offering excellent performance and stability.

5. Caddock's MP Series

Specifications: The MP series offers power ratings from 1W to 50W, with resistance values from 0.1Ω to 1MΩ.

Applications: Known for its precision, the MP series is suitable for high-accuracy applications in laboratory settings.

V. Comparison of Load Resistor Models

1. Power Handling

When comparing load resistors, power handling is a critical metric. Models like Vishay's RGP series and Caddock's MP series excel in this area, making them suitable for high-power applications.

2. Thermal Stability

Thermal stability is essential for maintaining performance under varying temperatures. Ohmite's 2W series and TE Connectivity's R-1 series are known for their excellent thermal characteristics.

3. Reliability

Reliability is crucial in applications where failure is not an option. Bourns' 3300 series and Vishay's RGP series are recognized for their robust construction and long-term reliability.

B. Cost Analysis

Cost is always a consideration when selecting components. While high-performance models may come at a premium, they often provide better long-term value through reliability and performance.

C. User Reviews and Feedback

User reviews can provide valuable insights into the performance of load resistors. Many users praise Vishay and Ohmite for their consistent quality and performance in demanding applications.

VI. Selecting the Right Load Resistor

1. Application Requirements

Understanding the specific requirements of your application is crucial. Consider factors such as power rating, resistance value, and environmental conditions.

2. Environmental Conditions

If the load resistor will be exposed to extreme temperatures or humidity, choose a model designed to withstand these conditions.

3. Budget Constraints

While it's essential to invest in quality components, it's also important to stay within budget. Evaluate the cost versus performance to find the best fit.

B. Tips for Choosing Load Resistors

Research: Look into various models and manufacturers to find the best options for your needs.

Consult Experts: If unsure, consult with engineers or industry experts for recommendations.

Test: If possible, test different models in your application to determine which performs best.

VII. Conclusion

A. Summary of Key Points

Load resistors are vital components in electrical engineering, serving various applications from testing to power electronics. Understanding their features and specifications is essential for selecting the right model.

B. Future Trends in Load Resistor Technology

As technology advances, load resistors are expected to become more efficient, compact, and capable of handling higher power levels. Innovations in materials and manufacturing processes will likely lead to improved performance and reliability.

C. Final Thoughts on Selecting Load Resistors

Choosing the right load resistor involves careful consideration of application requirements, environmental conditions, and budget constraints. By understanding the available options and their features, engineers can make informed decisions that enhance the performance and reliability of their electronic systems.

VIII. References

- Academic Journals on Electrical Engineering

- Manufacturer Websites for Load Resistors

- Industry Standards and Guidelines for Resistor Selection

This comprehensive overview of popular load resistor product models provides valuable insights for engineers and enthusiasts alike, ensuring they can make informed decisions in their projects and applications.